Value, integrity, reliability and professionalism have been the cornerstones on which we have built our business.

We understand what our customers want and have implemented procedures, employed people and purchased equipment to ensure that we can respond to a market that is dynamic and demanding shorter lead times and faster responses in terms of artwork approval, quotations and deliveries.

- We have dedicated internal sales administrators whose sole purpose is to ensure that we give our clients the best possible service.

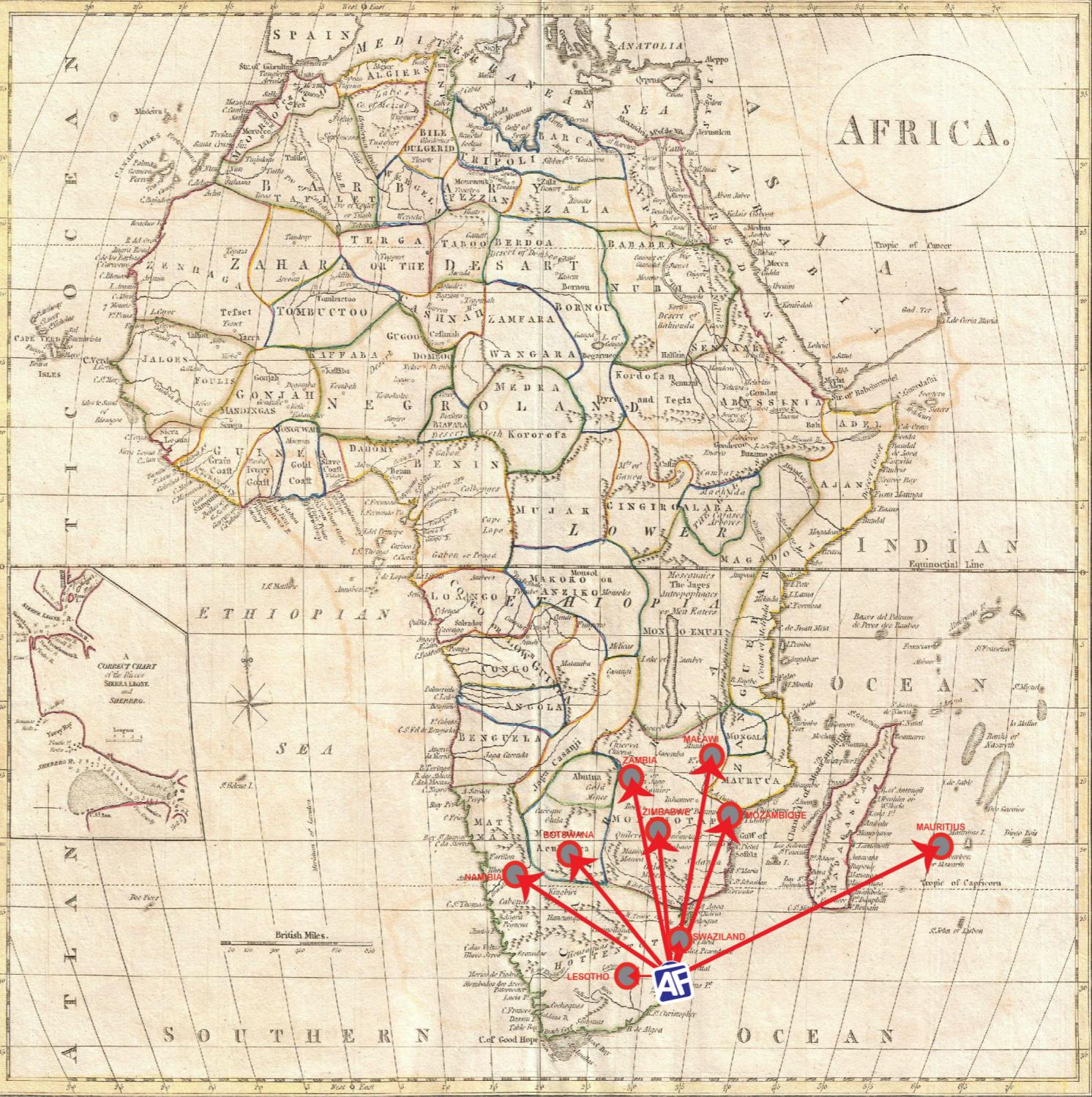

- From our manufacturing facility in Durban, we supply nationally and export into Africa.

- We have 5 NIL PETER combination printing presses. They are capable of printing supported and unsupported film e.g. self-adhesive labels and shrink-sleeves.

- Because we have standardized our printing presses and all our tooling is common, we have greater flexibility as we are able to print any job on any press.

- In our experience, NIL PETER printing presses offer the greatest innovation, flexibility, reliability and back-up service in the industry.

- Our inspection rewinders have camera inspection systems to ensure that supply consistently high-quality print.

- In terms of cutting/finishing equipment, we have invested in state-of-the-art equipment as used by some of the largest printing companies in the world.

- Our shrink-sleeve finishing equipment offers the latest technology with regards to consistency, quality and efficiency.

- In short, we have invested in the best equipment available to ensure that we can offer our clients printed packaging that will compete on a global level.